Description

| Specification | Detail / Value (Based on 2 mm Series) | Notes |

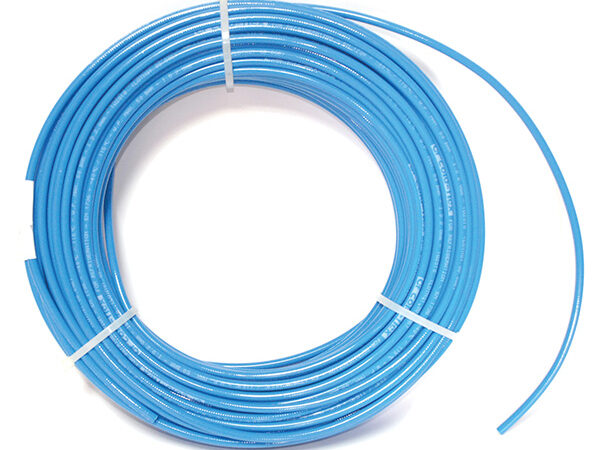

| Product Name | COLDFLEX 404 | Part of the 2 mm flexible hose line. |

| Product Type | Flexible Capillary/Instrumentation Hose | Used for pressure sensing, not bulk flow. |

| Color | Blue | Used for visual identification, often designated for the low-pressure side or specific control circuits in refrigeration. |

| Inner Diameter (ID) | 2.20 mm | The precise inner measurement. |

| Outer Diameter (OD) | 5.65 mm | Ensures proper fit with standard Cold-Flex fittings |

| Construction Standard | Meets or Exceeds EN 1736 | The European standard for flexible refrigerant hoses and assemblies. |

| Max Working Pressure (WP) | 50 bar (tested 350 bar proof pressure ) | The maximum sustained safe working pressure. Note: The hoses have an extremely high burst rating (often 700 bar or more). |

| Burst Pressure | Tested to exceed 1000 bar ( ex 1028 bar) | Provides a massive safety margin. |

| Refrigerant Compatibility | Tested for low permeability with refrigerants like R410A | Ensures minimal refrigerant loss over time, meeting EN 1736 standards |

| Minimum Operating Temp | Cold Flexible Rating (Typically -20 C or lower) | Maintains flexibility in cold environments. |

Essential Features

- Vibration Elimination: This is the core purpose. The hose provides a flexible connection that dampens vibrations from compressors and other moving parts, ensuring connected manometers, transducers, and pressure switches receive stable, accurate signals.

- High-Pressure Safety Margin: The construction includes internal reinforcement (braiding) to achieve very high burst pressure (over 1000 bar), providing exceptional safety and durability under continuous working pressures up to 50 bar.

- Low Permeability: Critical for closed refrigeration systems. The material is designed to minimize the diffusion of refrigerant (like R410A) through the hose wall, leading to long-term system efficiency.

- Color Coding (Blue): In line with standard HVAC/R practices, the Blue color allows technicians to immediately identify the line, often corresponding to the low-pressure/suction side of the system.

- Refrigerant/Oil Resistance: The polymer used is selected for its resistance to both the gas/liquid refrigerant and the lubricating oils within the system.

Reviews

There are no reviews yet.