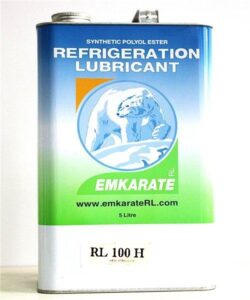

Description

❄️ EMKARATE RL46H Technical Data

| Analysis | Method | Typical Value | Unit |

| ISO Viscosity Grade | VG 46 | ||

| Viscosity @ 40°C | ASTM D445 | 45.3 – 46.8 | cSt (mm^2/s) |

| Viscosity @ 100°C | ASTM D445 | 7.1 – 7.3 | cSt (mm^2/s) |

| Viscosity Index (VI) | ASTM D2270 | 116 – 121 | |

| Density @ 20°C | ASTM D1298/D4052 | 0.977 – 0.978 | g/ml |

| Pour Point | ASTM D97/D5950 | -46 to -48 | circC |

| Flash Point (COC) | ASTM D92 | 242 – 260 | circC |

| Total Acid Number (TAN) | ASTM D974 | 0.02 – 0.05 | mgKOH/g |

| Water Content | ASTM D6304 | leq 40 | ppm |

| Color | ASTM D1500 | leq 0.2 / Pale Yellow |

Key Features

-

Optimal Viscosity Grade: ISO VG 46 provides a balance of low-temperature flowability and high-temperature film strength for effective lubrication.

-

Excellent Miscibility: Engineered for outstanding miscibility and solubility with HFCs, which is critical for efficient oil return to the compressor from the heat exchangers, preventing oil-logging and maintaining system efficiency.

-

Superior Wear Protection: Provides effective wear protection for all metal surfaces (steel and aluminum), prolonging the life of the compressor.

-

High Purity: Characterized by very low acid value and low water content, ensuring long-term chemical stability and protection against corrosion and system breakdown.

-

Low-Temperature Flow: The very low pour point ensures the oil remains fluid and can circulate freely, even in cold evaporator environments.

-

OEM-Approved: The RL series, including RL46H, is highly OEM-approved and recommended for both initial factory fill and service/retrofit applications.

-

Retrofit Capability: Compatible with residual mineral or alkylbenzene oils remaining in systems being retrofitted from CFC/HCFC to HFC refrigerants (though thorough clean-out is always recommended).

Reviews

There are no reviews yet.