Description

⚙️ S95B Technical Data

The S95B is built for the highest loads and flow requirements within the standard BPHE range.

| Specification | Detail |

| Model Code Structure | S95B – XX H (where XX = Plate Count, H = High Pressure) |

| Max. Working Pressure | 5.0 MPa (50 bar) |

| Working Temperature | -196^C to +225^C |

| Plate Material | SUS 316L / SUS 304 (Often standard 316L due to demanding industrial use) |

| Brazing Material | Copper (Standard) or Nickel (For ammonia/industrial fluids) |

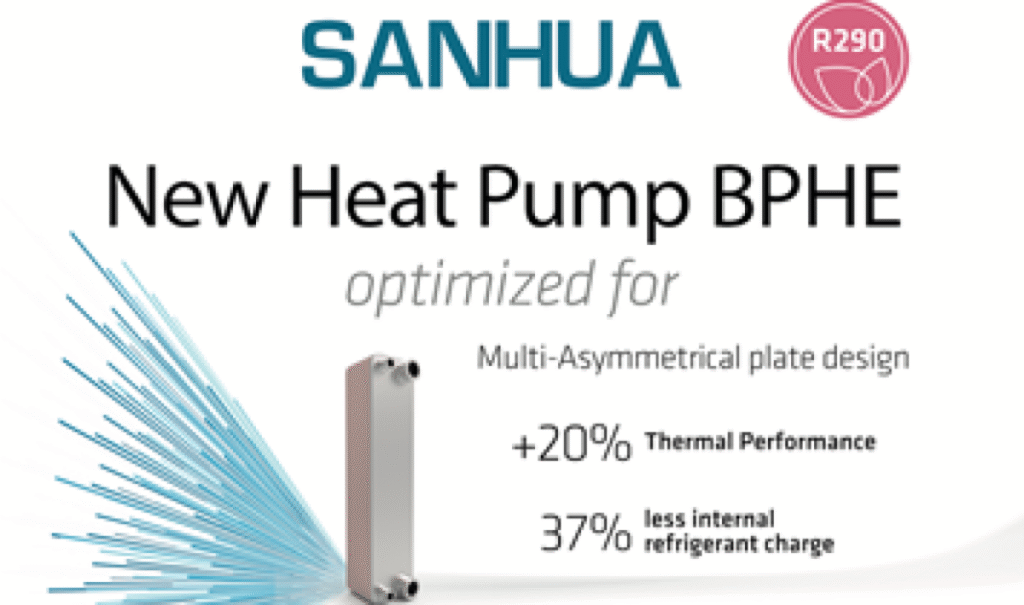

| Compatibility | R410A, R32, R290, and all common industrial refrigerants/fluids. |

| Capacity Range | approx 30 kW to 200 kW (depending on N) |

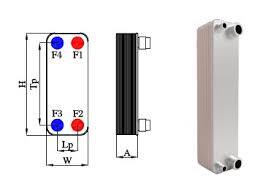

| Approx. Dimensions (W x H) | 196 mm times 621 mm (Plate Pack – Very Large) |

| Max. Flow Rate (m^3/h) | Very High, approx 10 m^3/h or more. |

🔢 Models Defined by Plate Count (N)

The S95B is a physically large unit, accommodating the highest plate counts among the standard series to achieve maximum capacity.

| Model (Example N) | Capacity (≈kW R410A Evap.) | Application Context |

| S95B-20H | approx 60 kW | Light duty for a large frame, high Delta T requirements. |

| S95B-40H | approx 120 kW | Standard unit for commercial screw/centrifugal systems. |

| S95B-60H | approx 180 kW | High end capacity for large modular systems. |

| S95B-N H | Capacity N | Can be manufactured with up to approx 80 plates. |

Key Features (Technical Characteristics)

-

Maximum Nominal Capacity (S95): Largest plate size in the standard refrigerant-to-fluid range.

-

Asymmetric Plate Design: Optimized channel geometry for minimal pressure drop.

-

High Design Pressure (5.0 MPa): Robust structure for high-pressure refrigerants.

-

Optimized Distribution: Advanced distribution channels for uniform flow across the large plate area

Reviews

There are no reviews yet.