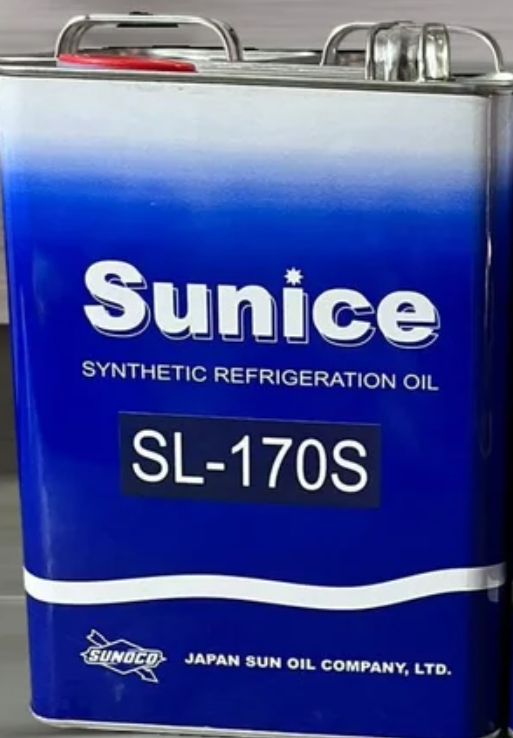

Description

🧊 Suniso SL 170 Technical Details

Key Technical Specifications

| Property | Value (Typical Analysis) | Unit | ASTM Method (Common) |

| Type | Polyol Ester (POE) | N/A | N/A |

| ISO Viscosity Grade (VG) | 170 | N/A | ISO 3448 |

| Kinematic Viscosity @ 40°C | 167.8 – 170 | cSt (mm^2/s) | D445 |

| Kinematic Viscosity @ 100°C | 15.3 – 17.2 | cSt (mm^2/s) | D445 |

| Viscosity Index (VI) | 109 | N/A | D2270 |

| Density @ 15°C | 0.969 – 0.990 | kg/L | D4052 |

| Pour Point | -27 / -17 to -24 / -11 | ^C / ^F | D5950 / D97 |

| Flash Point | 260 / 500 to 279 / 534 | ^C / ^F | D92 |

| Water Content (Moisture) | < 100 | ppm | D6304 |

| Acid Value | < 0.1 | mg KOH/g | D974 (Modified) |

🌟 Key Features of Suniso SL 170 (POE)

-

POE Synthetic Base: It is a fully synthetic Polyol Ester (POE) lubricant, which is mandatory for use in systems running modern HFC refrigerants.

-

HFC Compatibility: Specifically formulated for use with ozone-friendly HFC refrigerants such as R-134a, R-404A, R-407C, R-410A, and R-507A, as well as many new HFC/HFO blends.

-

Superior Miscibility: Exhibits exceptional miscibility with HFC refrigerants, even at very low temperatures. This is a critical feature that ensures the oil leaves the evaporator and returns to the compressor, guaranteeing continuous lubrication and preventing oil logging.

-

High Thermal Stability: Possesses a very high Flash Point (typically 260^C to 279^C). This indicates outstanding resistance to thermal breakdown, minimizing the formation of carbon deposits and sludge at the compressor’s high-temperature discharge area.

-

Optimal Viscosity Retention (ISO VG 170): The ISO Viscosity Grade of 170 is high, providing a robust lubricating film to reduce friction and wear on critical components (like bearings) in large or heavy-duty compressors (especially screw compressors). Its formulation ensures it maintains this protective viscosity even when diluted by the refrigerant.

-

Excellent Low-Temperature Performance: It maintains good fluidity with a low Pour Point (approx -27^C). This prevents the oil from congealing or waxing in cold system components, ensuring oil flow and system reliability.

-

Corrosion Protection: Contains special additives to provide outstanding protection against corrosion for both steel and aluminum surfaces within the system.

-

Low Moisture Content: It is manufactured to stringent standards with very low initial moisture content (< 100 ppm), which is vital for system longevity.

Reviews

There are no reviews yet.