Description

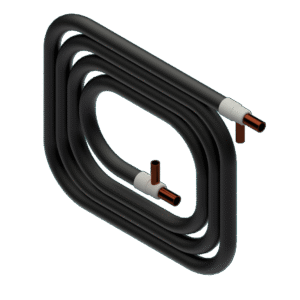

Core Design and Construction

| Specification | Detail |

| Design Type | Coaxial Tube-in-Tube (Shell-and-Coil) |

| Geometry | Double Wound Helix (The tubes are helically coiled, often providing two separate circuits or a specific internal flow path). |

| Flow Arrangement | Counterflow (Optimal for heat exchange efficiency). |

| Refrigerant Flow | In the Annular Space (between the inner and outer tube). |

| Water/Brine Flow | Through the Inner Tube (coil). |

| Key Technology | Patented Convoluted Multi-Lead Inner Tube: This unique surface geometry increases the effective heat transfer area and creates turbulence on both the water and refrigerant sides, significantly improving the heat transfer coefficient ($\mathbf{U}$). |

| Anti-Fouling | The turbulent flow characteristics effectively scour the inner tube walls, providing superior resistance to scaling and fouling compared to smooth-tube exchangers. |

| Outer Shell Material | Carbon Steel (Standard). |

| Inner Tube Material Options | Copper COAX: Standard material for fresh water/cooling tower applications. 90/10 Cupronickel COCX: For use with ground loops, lake water, or marine applications (corrosion resistance). |

2. Pressure and Certification Ratings

The Classic Double Wound Helix models are built to a high standard, accommodating modern refrigerants:

| Rating | Value |

| Max. Refrigerant Working Pressure | 650 psig (4482 kPa) |

| Max. Water Working Pressure | 500 psig (3447 kPa) |

| Compatibility | Fully compatible with all common refrigerants (R-410A, R-134a, R-22, etc.). |

| Certification | C-UL-US Listed (Certified by UL and CSA). |

Double Wound Helix: Design and Safety

Available Classic Models

The double wound helix refers to the construction of the inner tube that facilitates both high efficiency and crucial safety.

- Design: It consists of two layers of convoluted (corrugated) tubing—an inner primary tube and an outer secondary tube—wound helically and stacked one over the other. This creates a secure, double-layer barrier between the two fluid circuits.

- Safety Priority (Potable Water): This is the most critical feature. The double-wall construction ensures that if a leak were to occur in either the inner or outer barrier, the refrigerant (or other fluid) cannot mix with the potable water flowing inside the inner tube. This design is mandatory for codes requiring separation of refrigerant from drinking water.

- Leak Path to Atmosphere: Specific models often include a small leak detection void between the inner and outer walls. If a leak occurs, the refrigerant or water will escape through a detection port to the atmosphere, alerting maintenance personnel without contaminating the potable water supply.

Reviews

There are no reviews yet.