Description

❄️ HXR and LHXR Series: Core Technical Data

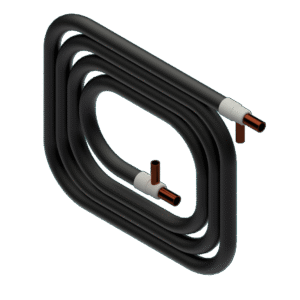

These exchangers utilize a straight-through coaxial design intended for intra-cycle heat exchange between the high-pressure liquid and low-pressure suction vapor.

| Specification | Detail |

| Design Type | Coaxial Tube-in-Tube (Straight-Through) |

| Heat Exchange | Liquid Refrigerant (High-Pressure) flows in the Annular Space (shell). |

| Heat Exchange | Vapor Refrigerant (Low-Pressure) flows through the Inner Tube (Suction Line). |

| Flow Arrangement | Counterflow (Maximizes heat transfer potential). |

| Key Technology | Patented Convoluted Multi-Lead Inner Tube to maximize surface area and impart turbulence to both refrigerant flows, ensuring high efficiency in a compact size. |

| Connections | ID Sweat Connections on both the vapor (suction) and liquid sides for easy brazing into the refrigerant lines. |

| Compatibility | Compatible with virtually all common refrigerants (HC, HFO, HFC, HCFC, & CFC refrigerants: R-22, R-134a, R-407C, R-410A, R-404A, etc.). |

| Certification | HXR models are UL Listed; LHXR models are UL Recognized. |

✨ Key Design and Performance Features

The high performance of Packless exchangers is attributed to their patented design:

- Convoluted Inner Tube: The inner tube is manufactured in a patented process that makes it convoluted (corrugated/helical). This is the key feature that:

- Significantly increases the heat transfer surface area in a compact size.

- Imparts turbulence to both the liquid and vapor refrigerant flows, enhancing the thermal performance (heat transfer coefficient).

- Counterflow Arrangement: The heat exchangers are designed for a counterflow direction (the two fluids flow in opposite directions), which provides the greatest mean temperature difference and yields optimum heat transfer.

- Liquid Subcooling: The hot liquidrefrigerant is subcooled before it enters the TXV (Thermostatic Expansion Valve), which prevents flash gas in the liquid line and improves the TXV‘s performance.

- Vapor Superheating: Any residual liquid in the suction line is evaporated, and the vapor refrigerant is superheated before entering the compressor.

- Compressor Protection: Eliminating liquid refrigerant from the suction line prevents liquid slugging, which can severely damage the compressor.

- Efficiency Boost: The subcooling and superheating processes together provide a small increase to system refrigerating capacity (though selection should avoid oversizing which could lead to excessively high return gas temperature).

Reviews

There are no reviews yet.